- Easy to install

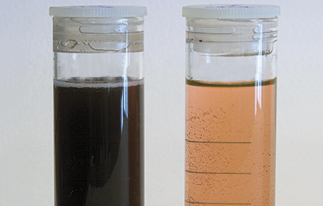

- Cleans and maintains coolant system from rust and contaminants

- Increases water pump life

- Reduces coolant deposits and increases cylinder head efficiency and life

- Stainless steel filter elements can be cleaned – NO WASTE

- Visual flow indicator (stationary applications)

- Easy to service – decreases maintenance cost

- Filter micron rating:

standard – 50 micron

optional – 25 micron - Flow rate up to 30 GPM

- Inhibits electro-chemical degradation of engine components. An industrial gas engine has the characteristics of a large battery when coolant is circulated through the engine block. Contaminants and suspended solids in the coolant act as a conductor, which more readily allows current to flow throughout the engine block, which degrades EPDM, buna, rubber, viton, and soft metal or alloy components / water pump bearings, impellers, etc.

- Cleaned coolant inhibits corrosion on engine components such as cylinder heads, cylinder liners and seals, water pump impellers and bearings, etc.

- Prevents “flash-off” in the cylinder heads when engine has an emergency stop; as the coolant can properly dissipate thermal loads

- Inhibits scale deposits on all coolant passages and interior thermal surfaces of the engine block.

Downloads

Contact

MOTORTECH GmbH | Hunaeusstrasse 5 | 29227 Celle, Germany | Phone: +49 5141 9399 0 | Send Email