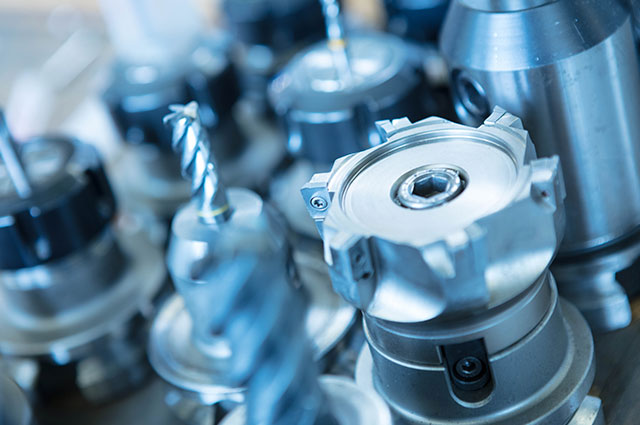

Six high-tech CNC machining centers and other precision machines for processing metal and plastic parts are available for the production of mechanical products. To achieve the greatest reliability, we use state-of-the-art laser technology to weld and mark parts. We often develop and build our own manufacturing equipment. There are often no optimal production machines on the market to produce our special system components that meet our rigorous standards. This means that we can produce exactly those products our customers need.

Our base modules are produced with state-of-the-art technology in small volume production runs in Germany and are marketed worldwide. These conditions make it possible to individually adapt the electronics to every engine type and set of requirements. Just plug it in and the engine runs. Replacement parts and components undergo extensive automatic test procedures and durability tests at MOTORTECH. Even the smallest system component must satisfy the high quality requirements of our “Zero Failure Strategy”.

MOTORTECH GmbH | Hunaeusstrasse 5 | 29227 Celle, Germany | Phone: +49 5141 9399 0 | Send Email